Benefits

- Different types of grooved rolls are available depending on the grain to process.

- Constant roller pressure for uniform material output.

- Large diameter shafts resist the high pressure of rolling grain.

- Can be integrated to your automated feeding system.

- 1-3/4'' (5 cm) Ø shafts

- High carbon steel hardened rollers (60 rockwell C)

- 5 or 7.5 HP motor

- Scraper kit for small grain rolls

- Metal object sensor magnets

- With or without discharge hopper

- Adjustable legs

- Hopper overflow protection switch Optional

- Horizontal or vertical discharge auger and its motor Optional

Low-cost processing of dry corn, wet corn, barley, and soybeans

Valmetal roller mills are mainly used to produce TMR in the dairy industry but also by microbreweries for the manufacture of beer. They crush barley and other grains used in the malting process.

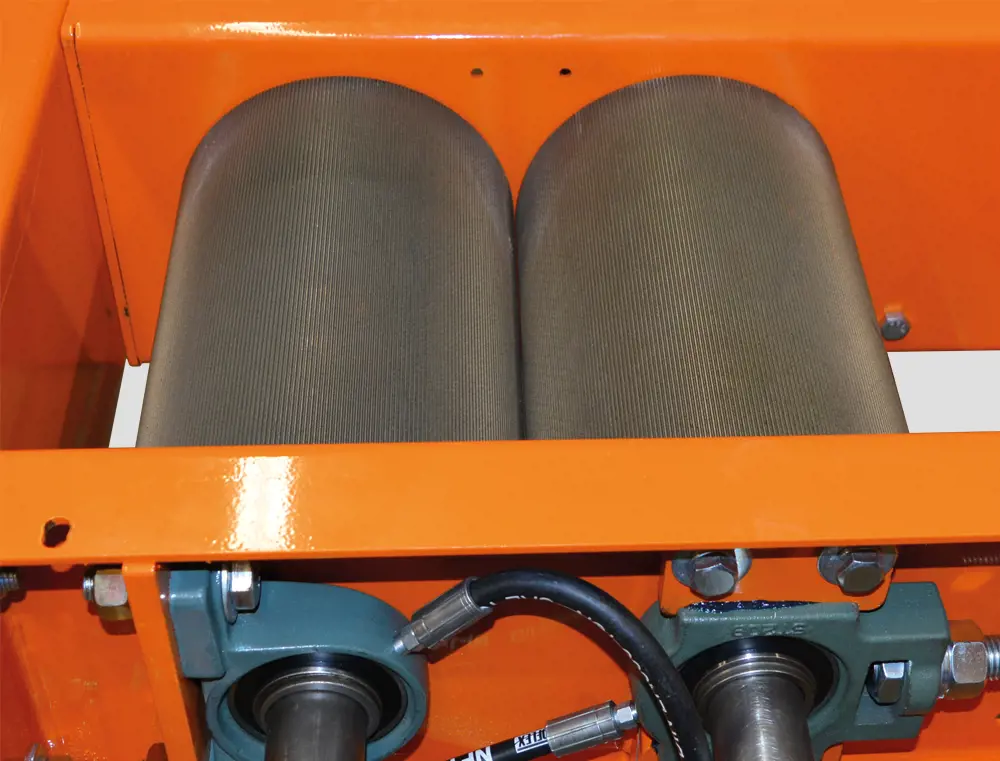

Grooved rollers

Rollers with 140 or 280 grooves are available depending on the desired grind texture. The 140 is used for corn while the 280 is used for smaller grains. The distance and the pressure they apply can easily be adjusted using one or two levers depending on your roller mill model. The pressure is maintained by a spring system.

Our 4R12 model includes 2 sets of rollers allowing you to process several types of grains with one machine.

Buy Valmetal equipment

150 dealers across the world to serve you. Get demos, specs, quotes & the expert guidance you need. Find your nearest dealer.

Subscribe to our newsletter

Subscribe for exclusive access to our new products, promotions, events, case studies, expert advice and more.