Benefits

- Fast mixing while being gentle on the fiber.

- Technology to reduce pressure on mixer components.

- Large mixing capacity, but still efficient with small rations.

- Low profile for easy filling.

- Abrasion resistant steel screw

- Polymer bottom liner

- Stainless steel end liners

- Angled rotor paddles

- Electric door opener

- 4-point weighbar load cell system

- Discharge conveyor Optional

- Extra cleaning blade on beater Optional

- Knives on upped auger Optional

- Magnet Optional

- Abrasion resistant steel screw

- Polymer bottom liner

- Stainless steel end liners

- Angled rotor paddles

- Hydraulic door opener

- 4-point weighbar load cell system

- Discharge conveyor Optional

- Extra cleaning blade on beater Optional

- Knives on upped auger Optional

- Magnet Optional

Perfect mixing

The wiper-edged rotor delivers perfect mixing of micro-ingredients, so every cow receives the ideal ration.

Automate your feeding system

Our automated feeding systems give you full control over every feeding process step: from filling and mixing to ration distribution. The high technology of the Autoration PRO Maestro allows you to operate multiple mixers and multiple scales simultaneously. Like this farm which benefits from significant time savings by feeding nearly 420 lactating cows with two TMR-Masters.

Ideal ration

The wiper-edged rotor delivers perfect mixing of micro-ingredients, so every cow receives the ideal ration.

Mix and distribute

The mobile version of the TMR-Master allows you to move around easily to distribute the RTM to the animals. A tractor of 100 HP (1000 RPM) or more is recommended.

Features

Mixing

The offset rotor arms provide plenty of tumble space while the angled paddles provide faster mixing.

Unloading

The 22” (56 cm) diameter lower auger unloads quickly and evenly. The electric powered rack & pinion door is standard equipment. (Order motor separately)

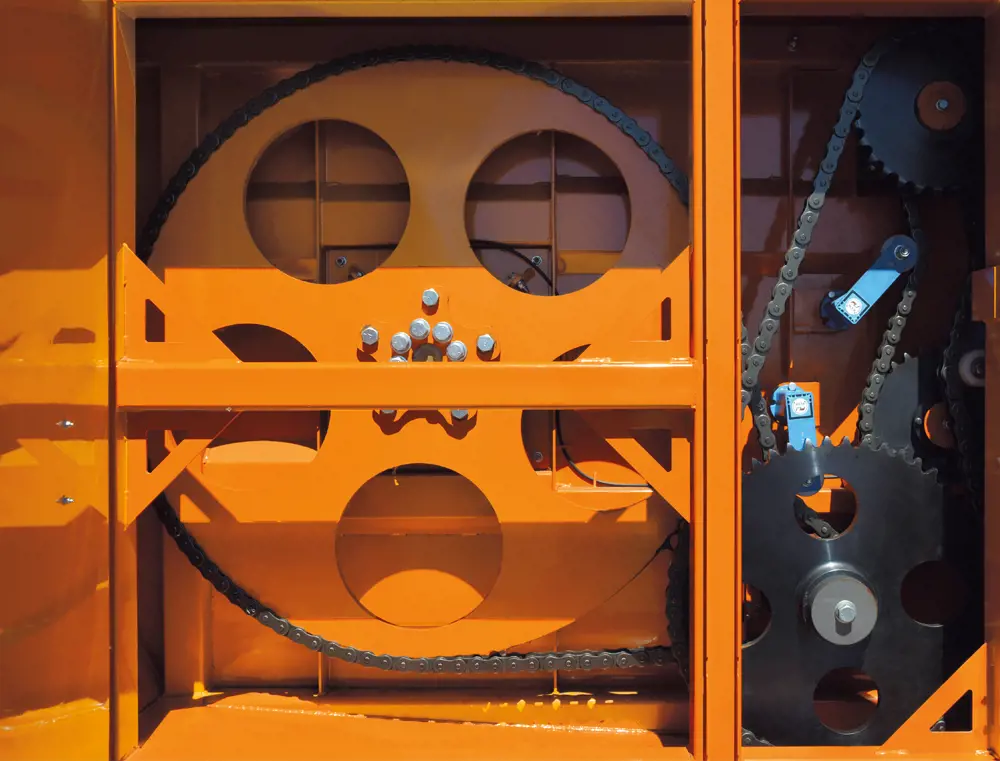

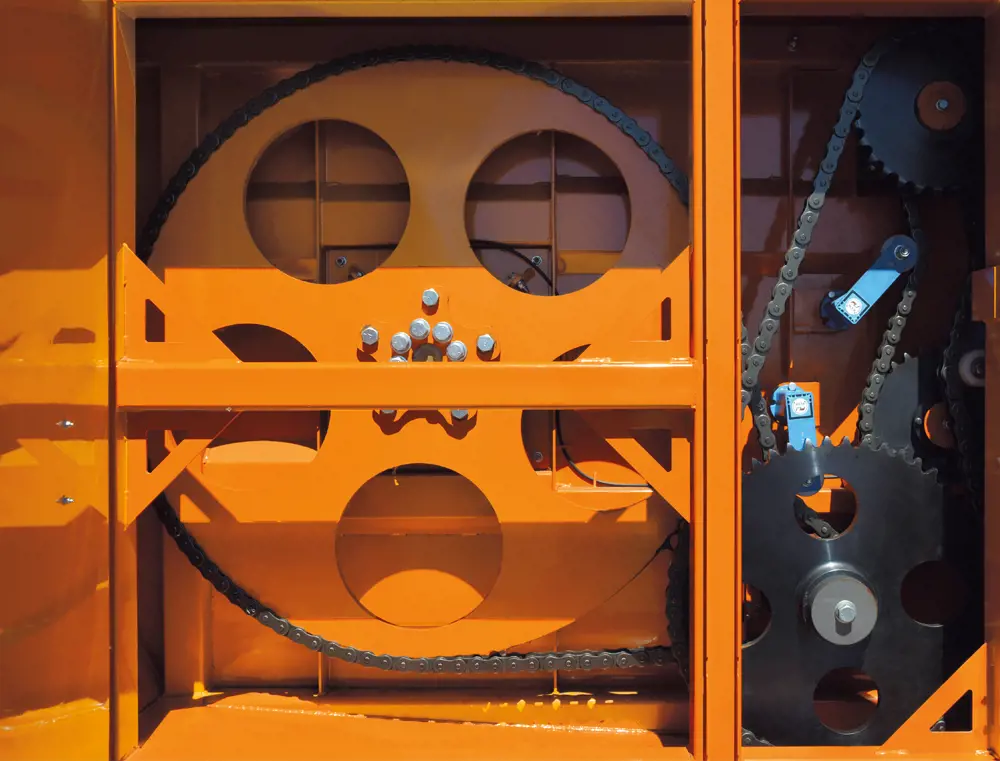

Drive system

Simple and robust, the TMR Master drive sys-tem requires little maintenance. The final chain drive is powered by a high-efficiency planetary drive with 4” (10 cm) diameter output shaft. Its large roller chains are self-lubricating in the oil bath and the bank of grease fittings is easy to access.

Features

Mixing

The offset rotor arms provide plenty of tumble space while the angled paddles provide faster mixing.

Unloading

The 22” (56 cm) diameter lower auger unloads quickly and evenly. The hydraulic powered rack & pinion door is standard equipment. (Order motor separately)

Drive system

Simple and robust, the TMR Master drive system requires little maintenance. The final chain drive is powered by a high-efficiency planetary drive with 4” (10 cm) diameter output shaft. Its large roller chains are self-lubricating in the oil bath and the bank of grease fittings is easy to access.

| Length | Width | Height |

| 212-1/2” (5.4 m) | 122-1/2” (3.1 m) | 96-1/2” (2.5 m) |

| Weight | Mixing capacity |

| 17,180 lb (7,795 kg) | 625 ft3 (18 m3) |

Specifications

| Length | Width | Height |

| 263-1/4'' (669 cm) | 124'' (315 cm) | 110-1/4'' (280 cm) |

| Weight | Mixing capacity |

| 16,100 lb (7,485 kg) | 625 ft3 (18 m3) |

Explore more equipment in this category

Buy Valmetal equipment

150 dealers across the world to serve you. Get demos, specs, quotes & the expert guidance you need. Find your nearest dealer.

Subscribe to our newsletter

Subscribe for exclusive access to our new products, promotions, events, case studies, expert advice and more.