Benefits

- Excellent maneuverability, even in tight spaces.

- Extremely accurate mixing, even in small loads.

- Gentle mixing action preserves fiber quality.

- Reduces feed shrinkage and increases ration accuracy.

- Low fuel consumption and minimum maintenance costs.

- Reduces feeding time and labor.

- John Deere Tier-5 diesel, 6 cylinder

- Self-cleaning / auto-reversing radiator

- LCD flat screen in the cabin monitors all operations

- 2 speed gearbox auger rotation, hydraulically operated

- Weighing system DG500 (4 sensors)

- High efficiency mechanical drive

- Air conditioning Optional

- Hay shredder knife kit Optional

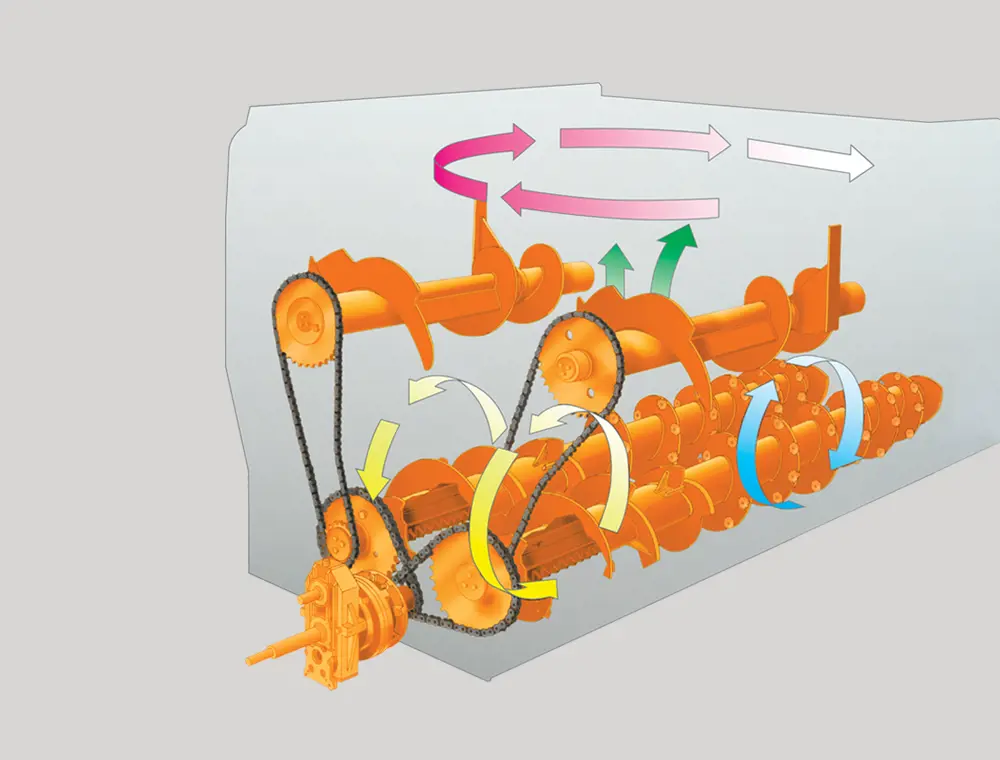

Unique cutting and mixing process (step 1)

It all starts with the high capacity loading arm, providing fast and precise loading of all types of silages, bales or commodities.

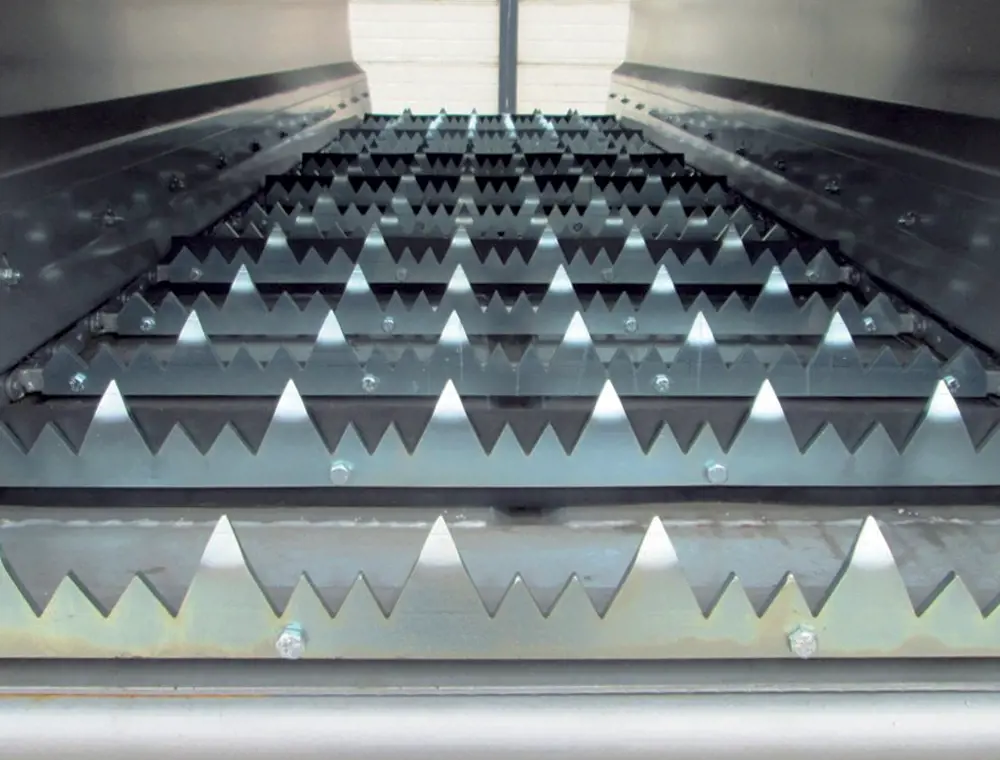

- Rotatable knives: The star-shaped knives are rotatable for long life and low maintenance cost. The unique shape ensures quick processing of hay while being gentle on silages.

Unique cutting and mixing process (step 2)

The two pairs of Hardox-400 horizontal auger take over to produce a homogeneous mix without compressing the ingredients.

- The full-length lower augers carry feed from the ends of the mixer, while the 3/4-length upper augers provide side-to-side mixing as they move feed towards the ends again.

- Knives and ledger bars are adjustable for clean and efficient cutting of long materials.

Maximum versatility

Loads all silages, commodities or bagged feeds quickly and precisely:

- The powerful bunk facer of the loading arm shaves bunkers clean, reducing feed loss.

- The hydraulic deflector prevents product leakage on very windy days.

- Bales can be easily loaded using the bunk facer, or dropped directly into the mixer with the optional hay knife kit.

Comfortable work environment

High visibility skycab to facilitate and control each step from loading ingredients to unloading of rations. All the options are at your fingertips!

- Wide door opening and air-ride seat

- Controls are easy to learn and to operate

- Armrest joystick control

- System display monitor and back-up camera

Features

Durable construction

Side walls are 3/8’’ (10 mm) thick and the bottom wall has an extra 3/16’’ (4 mm) stainless steel liner for maximum durability. Hardox 400 augers deliver maximum life.

High efficiency mixer drive

The mixer is driven by a gearbox and driveshaft, operating at much higher efficiency than hydrau-lic-drive system, saving fuel and reducing main-teance costs. The two-speed gearbox allows low-speed operation during filling to reduce wear and fuel consumption.

Unloading conveyor

The high speed discharge conveyor unloads feed quickly and evenly. Hydraulic conveyor tilt and door opening indicator are standard equipment.

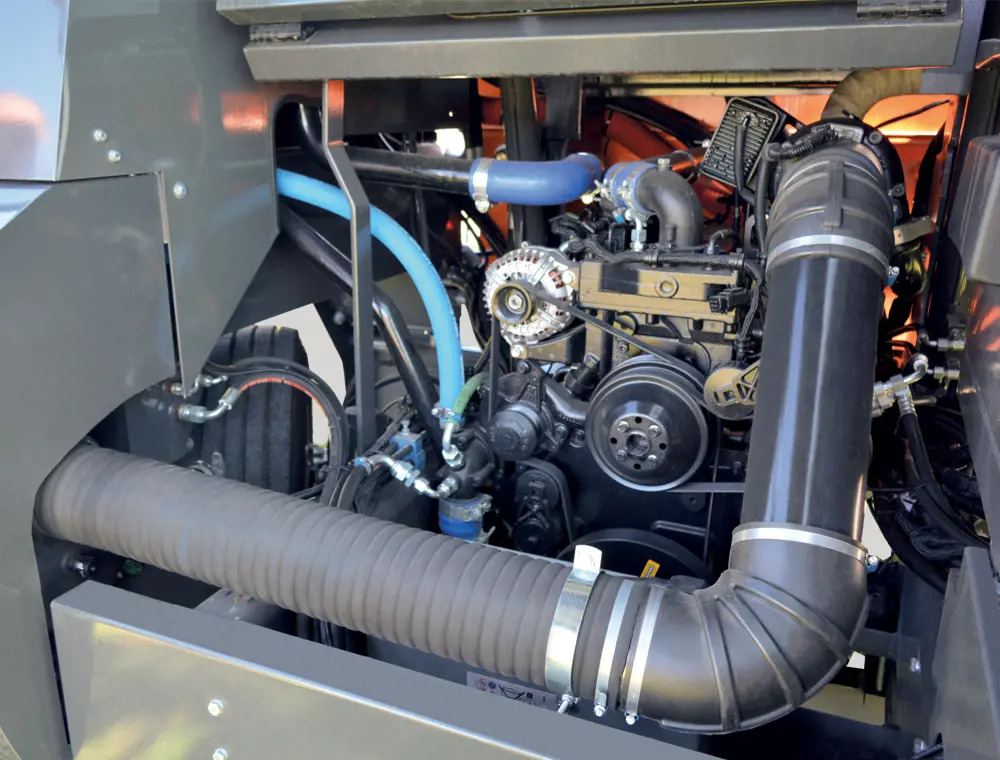

John Deere Power System Stage V

Offering excellent reliability and ease of service, the front-mounted John Deere engine powers both the mechanical mixer drive and the hydrostatic wheel drive.

Massive loading conveyor

The 35” (90 cm) high-speed loading conveyor delivers big volumes of feed for fast filling. It features stainless steel chains equipped with hay-hooks for fast loading of long fiber, and rubber wipers to ensure complete loading of minerals or other fine ingredients.

| Models | Mixing capacity | Dimensions* Width X Length X Height |

Motor power |

| SP-Mix 780 | 780 ft3 (22 m3) | 8 ft X 30 ft X 10.2 ft (2.4 m X 9.1 m X 3.1 m) | 129 kW / 175 HP |

| SP-Mix 850 | 850 ft3 (24 m3) | 8 ft X 32 ft X 10.2 ft (2.4 m X 9.8 m X 3.1 m) | 168 kW / 228 HP |

| SP-Mix 1060 | 1,060 ft3 (30 m3) | 8 ft X 34 ft X 10.8 ft (2.4 m X 10.4 m X 3.3. m) | 168 kW / 228 HP |

*The maximum height, when the loading arm is at its highest, is 16.4 ft (5 m).

Explore more equipment in this category

Buy Valmetal equipment

150 dealers across the world to serve you. Get demos, specs, quotes & the expert guidance you need. Find your nearest dealer.

Subscribe to our newsletter

Subscribe for exclusive access to our new products, promotions, events, case studies, expert advice and more.