Benefits

- Very quiet and low maintenance.

- High speed belt delivers large volumes quickly.

- Selection of accessories for a professional installation.

- Feed is delivered without any separation of fines.

- Sizes: 14’’ (36 cm) - 18’’ (46 cm) - 24’’ (61 cm) - 36’’ (91 cm) - 48’’ (122 cm)

- Sturdy sections in galvanized or stainless steel

- Wide choice of drive kits for standard, industrial, or special-speed applications

- Adjustable decline/incline sections from 0° to 35°

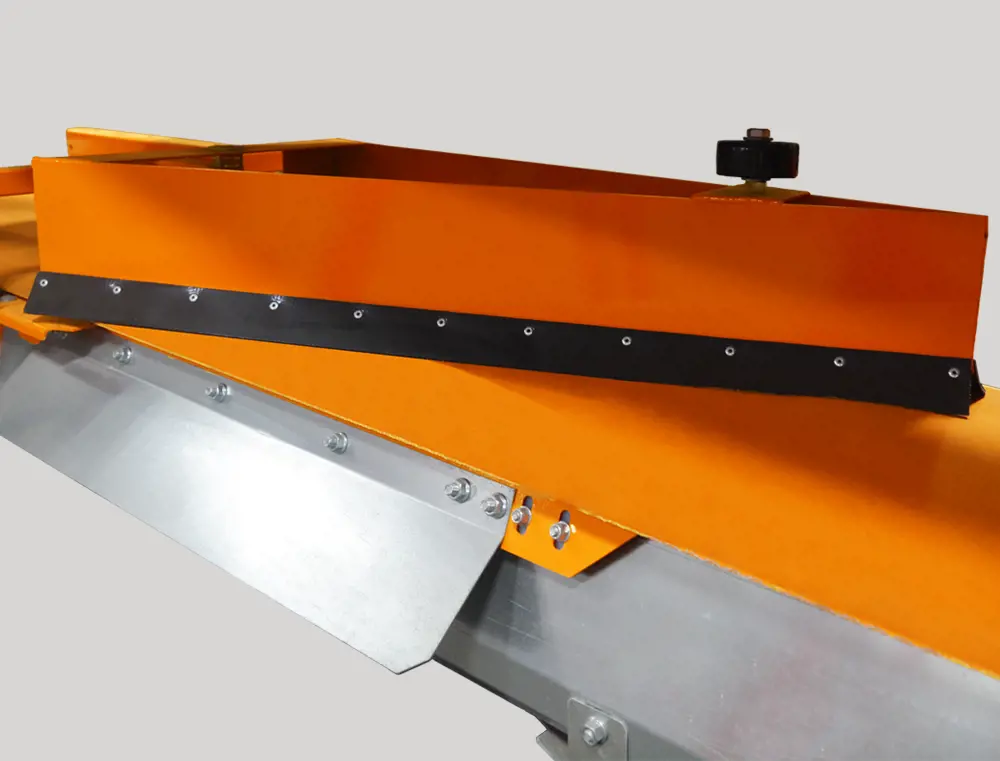

- Brush or scraper depending on the belt Optional

- Stationary plow Optional

- Side gaskets to prevent spillage Optional

Positive belt traction

The large diameter drive rollers are covered with a non-slip rubber for positive belt traction.

3 belt models

- Smooth Belt

Made of polyester and PVC, it is specially designed to remain flexible, even in extreme cold conditions (10° maximum angle). - Textured Belt

The textured surface provides more traction for the material, keeping it moving up most inclines (30° maximum angle). - Cleated Belt

The molded paddles keep material moving smoothly and evenly up steep inclines (45˚maximum angle).

Features

Hopper

Galvanized steel hopper eliminates spillage and centers feed on belt. Simple belt tightener maintains belt tension.

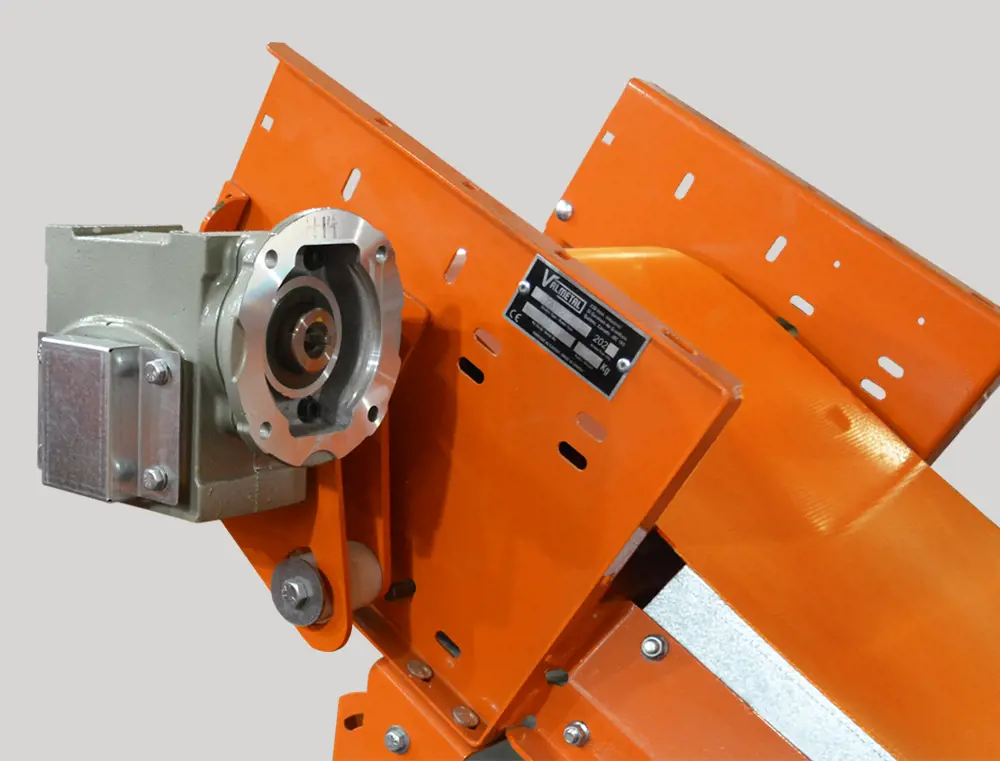

Motor and gearbox drive units

The gearbox-drive is compact and may be mounted on either side. Choose the standard model for most applications, or the industrial series for the most demanding jobs.

Stationary plow kit

The standard plow or the two-way plow will discharge material off the side, or will allow feed to pass when retracted. For smooth belt only, choose manual or electric control.

| Utility models | Standard models | Intensive-use models | Double-drive models | Special speed models |

|

60-series drive unit

|

70 & 80-series drive units

|

D-series gearboxes

|

|

Most Valmetal conveyors operate at high belt speeds to move large volumes quickly, however in applications that require less capacity, special-speed models produce lower belt speeds to save energy and wear. |

Expert help – there are many factors that affect the power requirement for a conveyor, including material density, material flow rate, incline, accessories, and site conditions. Your Valmetal expert is there to help.

Explore more equipment in this category

Buy Valmetal equipment

150 dealers across the world to serve you. Get demos, specs, quotes & the expert guidance you need. Find your nearest dealer.

Subscribe to our newsletter

Subscribe for exclusive access to our new products, promotions, events, case studies, expert advice and more.